PLM Consulting

PLM(Product Life cycle Management)

Consulting

AST supports the implementation and operation of PLM (Product Lifecycle Management) to optimize the entire product lifecycle—from planning and design to manufacturing, maintenance, and end-of-life (EOL). Backed by extensive industry expertise and a strong track record, we develop PLM strategies tailored to each client’s unique business characteristics and challenges. Our approach goes beyond IT deployment to include process redesign and stronger cross-functional collaboration, enabling true digital transformation (DX) and operational innovation. By addressing both systems and business processes, we help improve product development efficiency, enhance quality, reduce costs, and strengthen long-term competitiveness.

Process Optimization from Planning to Design

Connect information across product planning and design phases to enable effective data utilization from the early stages of development.

PLM Implementation & Operation Support

Promote practical PLM usage aligned with your operations—covering product structure management, change management, document control, and more.

Business DX and Adoption Support

Support process transformation based on your business characteristics, ensuring long-term adoption and continuous improvement.

How We Deliver Value

By seamlessly integrating a wide range of engineering tools, including CAD, CAM (Manufacturing), CAE (Analysis), and EDA (Electrical Design), we bridge the information gaps between design and manufacturing. Specifically, in the EDA field, we ensure the precise integration of bill-of-materials (BOM) and design data, maintaining alignment between electrical and mechanical designs. This approach significantly enhances product quality and drives operational efficiency, enabling us to provide impactful solutions that add value throughout the product lifecycle.

BOM Integration and Lifecycle ManagementBOM/BOP Consulting

In today’s product development projects, building and integrating various types of BOMs—such as EBOM, MBOM, and SBOM—each serving different purposes, is essential. Achieving effective variant management, change control, and quality assurance linked to BOMs is key to improving design quality and shortening lead times. At AST, we precisely capture your requirements and support the realization of BOM structures within your PLM system.

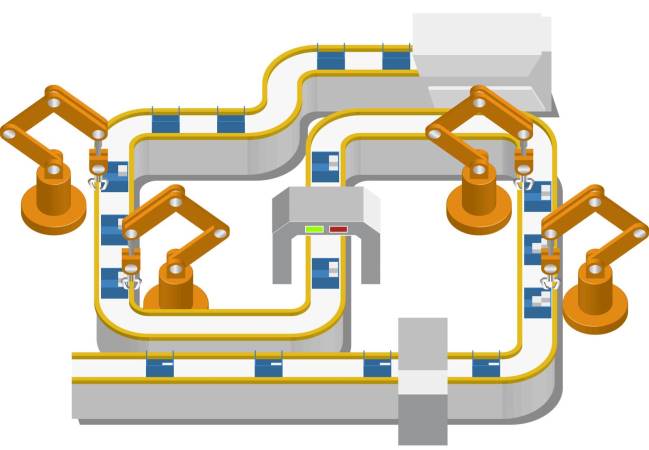

From Simulation to RealityProduction Engineering Simulation

To achieve right-first-time operation in production line commissioning, it is essential to digitally capture the manufacturing site and perform thorough production engineering validation. This includes capacity analysis and optimization of the production line, equipment behavior verification through robotic simulation, and robot offline programming. At AST, our experienced consultants support the successful implementation of these systems to help you build efficient and reliable production environments.

AST Strengths

AST’s strength lies in our consultants, who bring a wealth of industry knowledge specialized in manufacturing, combined with practical expertise gained through hands-on experience. This unique combination allows us to deeply understand your business operations and offer tailored support for the successful implementation and operation of PLM systems. We cover the entire product lifecycle—from planning and design through manufacturing, maintenance, and end-of-life (EOL)—and craft realistic strategies that align with your business needs and industry challenges. Whether addressing complex demands such as multi-CAD environments (including EDA systems), intricate BOM management, or production engineering validation, we offer flexible solutions to drive successful digital transformation (DX) and business process improvement. Our approach focuses on enhancing product development quality, reducing lead times, and strengthening cross-departmental collaboration through centralized information management—ultimately helping you build a competitive edge in the marketplace.

Expertise in Manufacturing Industries

Deep understanding of end-to-end business processes from design and production to maintenance.We provide tailored solutions that fit the specific needs of each industry and business model.

Comprehensive Support

We offer one-stop services covering everything from requirements definition and system implementation to operational rollout and user adoption.

User-Centered Support

We drive projects with a strong focus on usability and long-term adoption, incorporating feedback directly from frontline teams.