3DCAD Consulting

3DCAD

Consulting

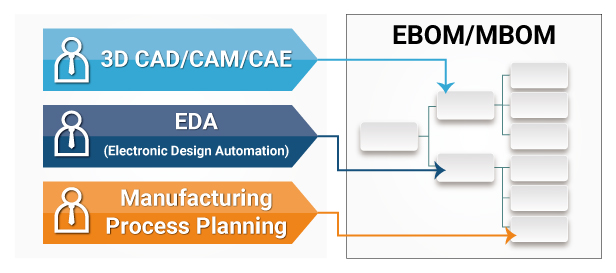

AST's 3D CAD consulting goes beyond simply supporting the implementation of CAD tools; it provides comprehensive support aimed at optimizing the entire design environment. Specifically, by seamlessly integrating and coordinating various systems, such as CAD, CAM (Manufacturing), CAE (Analysis), and EDA (Electrical Design), we prevent information gaps between design and manufacturing and enhance both design quality and operational efficiency. In addition to ensuring smooth data exchange and process alignment between tools, we also offer support for unifying operations across departments and establishing systems for knowledge sharing. Tailored to your unique design processes and product characteristics, we propose optimal configurations that maximize the performance of the entire engineering chain.

Implementation Support

We provide end-to-end support, from requirement gathering and tool selection to the creation of an implementation plan and actual system deployment.

Adoption Support

We assist with adoption through on-site training, creation of guidelines, and ongoing support for inquiries, ensuring successful implementation and integration into daily operations.

Process Optimization

We help review the entire design process and support the creation of efficient data management systems and design standards to streamline operations.

How We Deliver Value

By seamlessly integrating various engineering tools, such as CAD, CAM (Manufacturing), CAE (Analysis), and EDA (Electrical Design), we eliminate information gaps between design and manufacturing. In particular, in the EDA field, we ensure the accurate integration of bill-of-materials (BOM) and design data, maintaining consistency between electrical and mechanical designs. This powerful approach enhances overall product quality and drives operational efficiency.

Multi-CAD Integration SolutionsOptimizing Design Processes Across Multiple CAD Platforms

Our consultants, who are well-versed in the strengths of various CAD systems and are not tied to any specific vendor, help design and implement PLM systems based on an optimized multi-CAD environment tailored to your business needs. We propose solutions that leverage the unique strengths of each CAD system, ensuring flexible and effective implementation.

AST Strengths

Our strength lies in our deep understanding of industry-specific requirements and design processes, and our commitment to delivering systems that are actively used on the shop floor. We expertly handle the integration of design support tools such as CAD, CAM, CAE, and EDA, enhancing overall business coherence and efficiency. Without being dependent on any particular vendor, we focus on providing optimal solutions that address the unique challenges of each client.

Industry-Specific Focus

A deep understanding of industry-specific requirements and design processes.

Practical Approach

A commitment to delivering "used systems" with a focus on real-world application from the shop floor perspective.

Neutral Stance

A vendor-free, customer-centric problem-solving approach.